METALSPAN Focus

A1 ACM

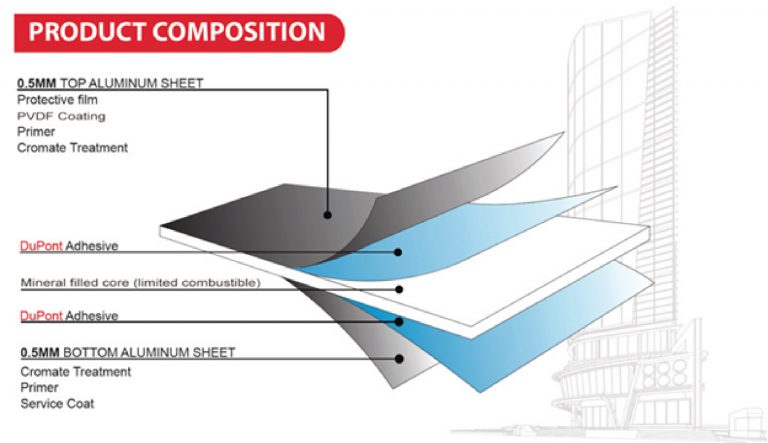

Our A1 ACM non combustible cladding material after continuos research into safety and performance of building facade materials.

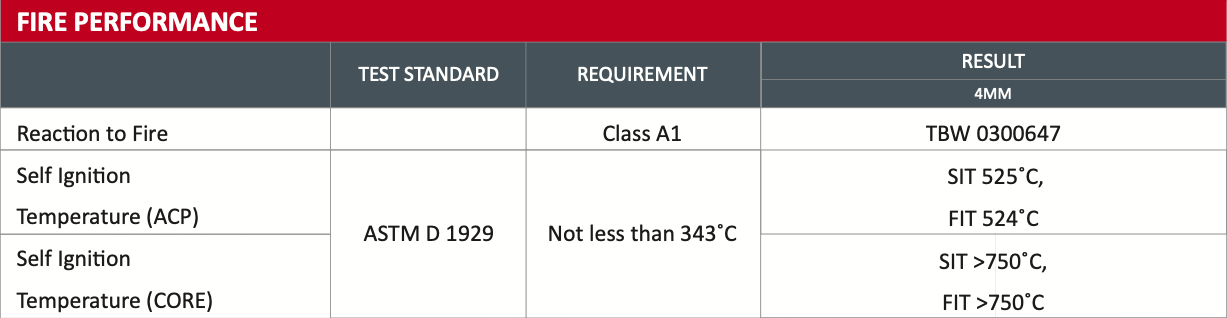

No. 1 for building facades with the highest fire protection requirement of class A1 classified under EN 13501-1. Our ALUCOPANEL® A1 is non-combustible. A sustainable alternative to façade materials made of metal or other cladding. Our product has passed ASTM D1929 standard which determines the Self and Flash ignition temperature of the product.

Fire Safety Standards

Testes completed and passed:

- BS EN13501-1 Reaction to Fire Test

- CWCT Rains Screen Cladding Test UK

- NFPA 285 : Full scale Fires Test System. First Dubai Civil Defence approved in the world

- AS 1530-1 Australian Standard

A1- Noncombustible ACM

Our new non combustible ACM has been tested to the highest standard of EN 13501-1 and acheived Euroclass A1 (A1 ACM - first time in the world)

- BS EN 13501-1-2018 – Classification of ACM products according to reaction to fire

- ASTM 1929 – Standard Test Method for determining ignition temperature of plastics

- NFPA 285 – US - Standard Fire Test Method for evaluation of the Fire Propagation characteristics of exterior - non - load bearing wall cladding assemblies containing combustible components

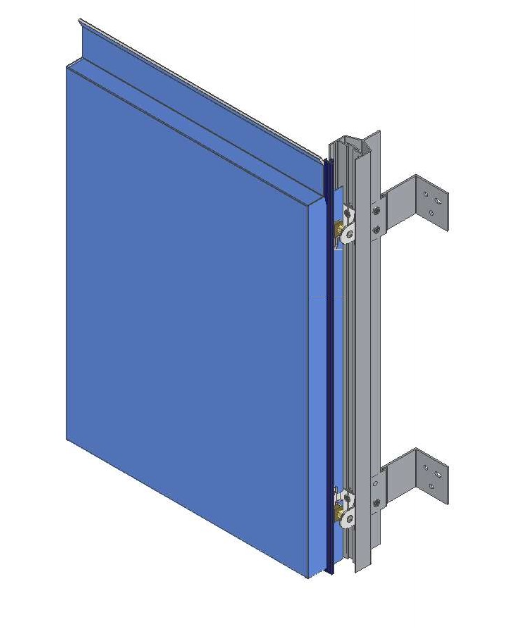

CWCT UK Rainscreen Cladding Test

Advanced design and engineering helps METALSPAN to achieve pressure equalised rainscreen cladding systems with an individually ventilated panel design with Euro Class A1 Non-combustible ACM material

M-SPAN BETTERFIX-M01 or M-SPAN BETTERFIX-M03 each with their distinct features.

Our M-SPAN BETTERFIX rear ventilated hook systems provide the following benefits:

✅ Better rear ventilation

✅ Better thermal performance

✅ Lower carbon emissions and energy efficiency

✅ Say no to oil canning effect faced by Solid Aluminium

✅ Maximum fire safety

✅ Range of PVDF colours solid and natural series

Machining and Fabrication

Machining and Fabrication Properties of Alucopanel A1 provides designers, fabricators, and installers with a high degree of flexibility.

- Routing

- V-groove cutting

- Bending – folding

Coating Performance

Coating Performance Tests Passed by Alucopanel ® A1 include (amongst others):

- ASTM C 481 – Weathering Resistance

- AAMA 2605 - Corrosion Resistance

- ASTM D 968 - Abrasion Resistance

- ASTM D 3363 - Pencil Hardness

- ASTM D3359 - Film Adhesion

- ASTM D2794 – Impact resistance

- ASTM D1400 - Coating thickness

Mechanical Performance

The Mechanical Performance of Alucopanel ® A1 has been thoroughly vetted.

- ASTM D 1781 – Peel off test